How Audience Targeting and Workflow Improvements Generate Big Wins for Thompson Direct Marketing

How Audience Targeting and Workflow Improvements Generate Big Wins for Thompson Direct Marketing

For marketers, selecting the right vendor partner makes the difference when it comes to production workflow and cost savings

The cumbersome, multi-step process used for most Medicare mailings is not sustainable in today’s ultra-competitive healthcare market. Thompson Direct Marketing, a company specializing in the production of Medicare and Medicaid mailings for non-governmental organizations, had used a traditional hybrid print workflow when producing its direct mail pieces. Then in 2017, the company’s printer partner came forward with a new print workflow option.

Because of its partner’s suggested change, Thompson was able to shift to the new workflow, reap the time and cost saving benefits, while continuing to target its audience appropriately with its direct mail without disruption.

Navigating the Medicare Direct Mail Waters

When it comes to healthcare insurance supplements, the options are endless. For someone planning for or just entering retirement, the prospect of choosing the right plan can be overwhelming, especially when presented with so many choices and with so much on the line. It’s critical to get it right.

According to the National Committee to Preserve Social Security and Medicare (NCPSSM), there are 56.8 million people currently enrolled in Medicare. The overwhelming majority — 47.8 million individuals — are enrolled due to their age, while 9 million are enrolled due to some form of disability. That’s a huge market, and numerous companies are vying for those dollars.

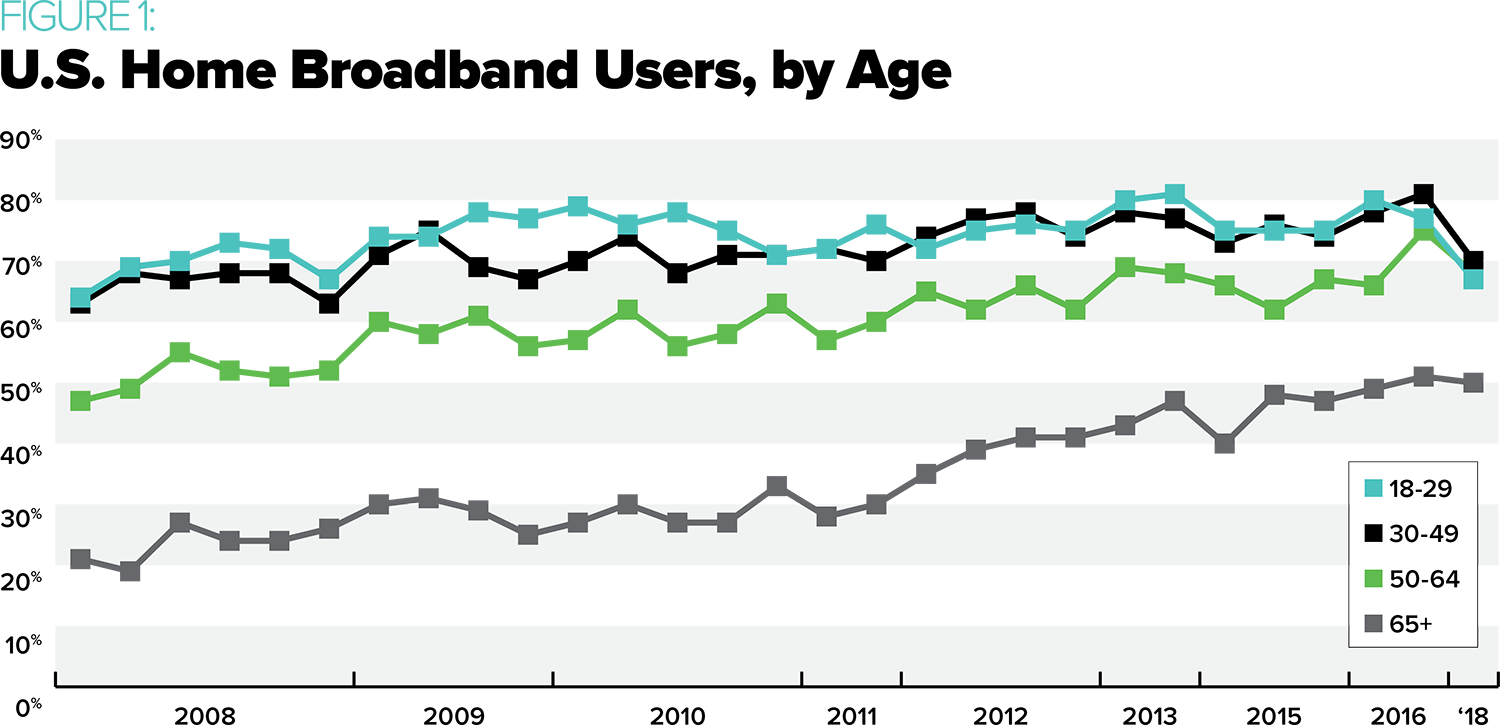

For retirees — a demographic that has lower Internet and social media usage than the overall population — direct mail remains one of the most effective ways to reach them.

According to Pew Research, more than one-third (34 percent) of seniors don’t use the Internet. In part, this is due to low broadband penetration, with only 50 percent of people over 65 years old having broadband at home. Although this percentage rises to 87 percent of those with household incomes above $75,000, it drops to 27 percent of those with household incomes below $27,000. Some seniors do have Internet access via their smartphones. However, one-third have no Internet access at all. That’s a large target market that cannot be reached using digital communications.

Even seniors who do have Internet access are not likely to make complex decisions about Medicare based on online research alone. In part, it’s because direct mail is easier to read and understand. Studies like those from Canada Post, Temple University and the Bangor University/Millward Brown have shown that information communicated in print is embedded more deeply in the brain and the details more easily recalled.

But it’s also a matter of trust. Members of the Silent Generation (those born between 1925-1945) are the most likely to trust marketing information that comes in the mail. According to one survey, 83% of the Silent Generation trust direct mail marketing, higher than any other generation.

While home broadband use has increased nearly 30 percent for consumers aged 65-plus in the past 10 years, it’s still approximately 18 percent below the other age groups. Source: Pew Research

Tailoring Healthcare Direct Mail for the Target Audience

To ensure any direct mail campaign is successful, a marketer must first accurately define the target audience, and then understand their needs and wants in order to craft effective marketing messages.

Durant, Okla.-based Thompson Direct Marketing is owned and operated by Dave Thompson, who has served the Medicare market for more than 40 years. Due to his tenure and industry expertise, he knows that direct mail works best for his target audience of those aged 65 and up, especially in regard to healthcare.

“When it comes to things like Medicare and Medicaid plans, direct mail remains the most effective way to reach new customers,” says Thompson. “Television and radio can communicate general information, but when it comes to plan specifics and choosing the right plan, they want print.”

Because of the plethora of Medicare options available, Thompson educates retirees on their options before presenting them with details on specific plans. Mailers outline the options offered by the insurer, and recipients check off and mail back a reply card on the plans they are interested in.

“One mailer might talk about Medicare or long-term care,” explains Thompson. “Another might talk about final expenses or annuities. Each one gives recipients the opportunity to consider their options and request information on plans they think will work for them.”

Thompson’s “go to” format is a versioned 7 ½ x 14” trifold mailer personalized at the time of mailing. Clients can choose from different templates identified by a version code used for tracking, and versions vary by state. In some cases, he will create custom mailers for clients.

Thompson works closely with his clients to select the right list for their marketing goals. “People retire at different ages now, so list selection is not as simple as it used to be,” Thompson explains. “Some of my clients might target those just turning 65 years old in March or April. Others might target those turning 65 to 79 in September or October. Others might narrow it down to women or men or those in a specific income bracket. We’ve come a long way from selling simple ‘age lists,’ like we used to do in the 1970s.”

Regardless of the list chosen, Thompson uses a geographic restriction for 90 days to ensure that his clients are not sending to the same target audiences at the same time. As the responses come back, he scans the results and emails the client a PDF the same day.

In total, Thompson mails more than 1 million pieces every year.

Postcard messages featured personalized salutations, references to the recipient’s specific neighborhood and financial incentives. (Address information has been removed to protect privacy.)

Managing Cost Savings While Juggling Direct Mail Inventory Issues

For years, Thompson used a traditional hybrid workflow. He had shells offset-printed at one facility, then worked with Louisville, Ky.-based United Mail to overprint the shells with variable information and mail them. His account manager, Monique Stephens, coordinated the drop shipping and production, but the overall process was cumbersome and inefficient.

“When Dave placed an order, we’d pull the shells from the warehouse and overprint them with variable information, then move them to a different machine to be folded, perfed and mailed,” says Stephens. “It got the job done, but it wasn’t the most efficient way to do it.”

Shells would become out-of-date every October as the dated material expired. Material also would go out-of-date as state laws changed. “It was a constant guessing game to determine how many shells he would need to have on hand before they became obsolete,” says Stephens.

Heightening this challenge was that in order to receive the maximum price break, Thompson had to print a minimum of 80,000 shells each time. This locked him into a tiered pricing system that often forced him to order and warehouse more versioned material than he needed.

“Sure, we got maximum price breaks, but we ended up throwing out thousands of pieces every year,” Thompson recalls. “It wasn’t unusual for us to throw out $5,000 worth of inventory on a $20,000 order.”

When United Mail offered Thompson a more efficient and cost-effective way to manage his campaigns, he was all ears.

“I used to be tied to my desk, making sure that everything was working right. Now, [the workflow] runs so smoothly that I am freed up to spend time doing things I love. I don’t have to constantly be forecasting and managing inventory.”

Dave Thompson

owner

Thompson Direct Marketing

Boosting Efficiency by Changing Workflow

In December 2017, Thompson was approached by Doug Prater, his sales executive at United Mail, about making a change to the way his mailings were handled. Prater suggested switching to a new print workflow available at United Mail due to a new press installation, which would allow the company to print, fold and mail Thompson’s pieces, all in one process.

This would be a major change in the way Thompson’s mailings were handled. Instead of overprinting pre-printed offset shells, everything would be printed on the fly. There would be no more shells. No more warehousing. All of the contents of the document, both static and personalized elements, would be printed at once. White paper in, full-color documents out, also known as a “white paper workflow.”

For Thompson, it would save a full five to seven days, compared to storing, transporting and overprinting shells — a time savings of up to 40 percent. It would also eliminate the need for constantly monitoring inventory and over-ordering to ensure that he wouldn’t run out.

The change in workflow also would save money. “Not only would I not have to worry about making sure I had enough inventory (or printing too much inventory),” Thompson explains, “but I wouldn’t be paying for inventory I might never use. It would keep more money in my pocket.” The decision was an easy one.

One by one, Thompson used up his existing inventory from the old system. Then, as the inventory for each version was depleted, he switched over to the 100 percent white paper workflow.

“It didn’t take long to burn through the old inventory,” he says. “Within 30 days, I had used everything up. From that point on, all of our jobs have been run using the new process.”

You don’t hear this often, but the transition from one workflow to the other was seamless. “It just worked,” says Thompson. Having a proactive printer partner like United Mail who was able to identify a solution to save Thompson time and money, while also cutting waste, is a testament to the benefits of choosing the appropriate vendor partner.

“We are managing all of the components of the job rather than just a portion of them. But because the white paper workflow is so efficient, we can do more in the same amount of time.”

Monique Stephens

account manager

United Mail

Workflow Change Creates Undeniable Production Savings

Today, Thompson’s workflow looks very different than it did even a few years ago, now that all campaigns are run using the white paper workflow. There is no warehoused inventory. No waste. Paper is supplied locally, ensuring that there are no production delays while the paper is being ordered or shipped.

Each week, Thompson supplies United Mail with his projects, broken down by client and type of form. United Mail processes the orders, mails them and supplies him with a single report. “Once I place the order, all I have to do is wait for the jobs to land,” he says.

Even though United Mail is handling the entire workflow in-house, it still provides Thompson with a four-day turnaround. “We are managing all of the components of the job, rather than just a portion of them,” says Stephens. “But because the white paper workflow is so efficient, we can do more in the same amount of time.”

For Thompson, the primary advantage of the switch has been simplicity and cost savings. “I don’t have to buy half a million pieces and pay for them all at once,” he says. “I pay for what I use, when I use it.”

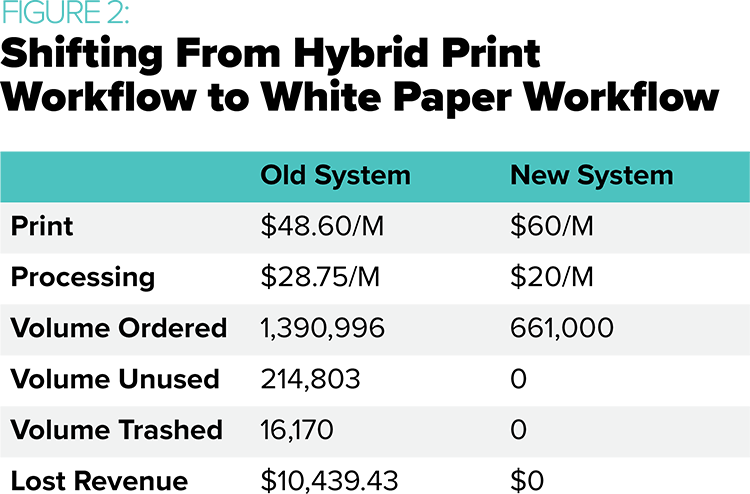

In the previous workflow, the volume ordered for the period July – December 2017 was 1.39 million pieces. Unused inventory was 214,000, or 15 percent of the total. Total lost revenue was $10,000 for that period.

Volume data, as reported by United Mail, was compiled using the most recent six months of which United Mail was operating under each system. For the new system, that was February – July 2017. For the old hybrid system, that was July-December 2017. The increase in volume in the old system is attributed to September and October being the highest-volume months for Thompson, due to open enrollment for Medical Insurance.

“Most of my pieces are printed with the date year, such as 2018 or 2019, and that changes over in October,” Thompson recalls. “As the October deadline would approach, I would see dollar signs disappearing with every day that passed. Between that, and losses due to changing regulations, there are times when I would throw away 100,000 pieces, translating into thousands of dollars. I don’t miss those days!”

Today, the volume of unused and trashed inventory is zero. The lost revenue is zero, too. Every piece that is printed gets mailed.

- Thompson does not have quality control issues, either.

- Bad quality barcodes = zero

Missing address blocks from BRC = zero - Versioned material being mismatched or switched = zero

Furthermore, Thompson no longer has to be concerned about how much inventory is in stock. “There were times in the past that my mailing would be delayed a week while the form was being printed,” he says. “Now, everything is being printed on the fly. That’s one less thing on my mind!”

Order delays are also a thing of the past. Today, the new white paper workflow is not only simpler and easier to manage, but by not paying for inventory he never uses, Thompson saves 25 percent on his production costs. “That’s real dollars that I can reinvest in my business or take home as profit,” he says.

But perhaps more importantly to Thompson, he gets to spend more time doing what he loves doing best — spending time with his family. This includes his new grandson. “I used to be tied to my desk, making sure that everything was working right,” he says. “Now, it runs so smoothly that I am freed up to spend time doing things I love. I don’t have to constantly be forecasting and managing inventory. I have more flexibility and can spend more time with my family. How do you quantify the benefits of that?”